-

Protos

Continue Reading

Continue ReadingScalable module concept

3 slots for variable combination with measurement or expansion modules. For pH, conductivity, and dissolved oxygen measurement.

Additional PID controller, probe controllers, PROFIBUS or Foundation Fieldbus.Protos

Modular hardware and software system for liquid analysis, in practical housing designs

• Protos 3400 S, tightly sealed stainless steel housing

with hygienic design

• Protos 3400 C, robust, corrosion resistant coated steel housingAllows world-wide operationVariPower adapter for supply from 20 … 254 V AC/DC, galvanically isolated measurement circuits, plus 2 current outputs and4 switched outputs in the standard versionScalable, modular hardware and software design

3 slots for variable combination with measurement or expansion modules. This allows for recording of up to 5 quantities simultaneously.

Control of fully automated calibration systems (probe controllers).Electronic data recording and backup

according to FDA 21 CFR Part 11

For use in food production or the pharmaceutical industry – Protos is the high-end transmitter. -

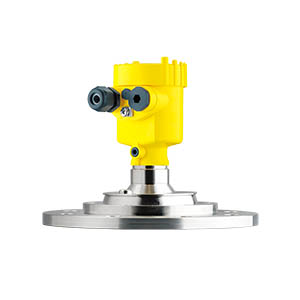

VEGAPULS 69

Continue Reading

Continue ReadingApplication area

Bulk solids in small up to large vessel heights

The VEGAPULS 69 is a sensor for continuous measurement of bulk solids under different process conditions. It is ideal for level measurement in very high silos, large bunkers and segmented vessels. Thanks to the very good signal focussing a simple setup and reliable measurement is ensured. The VEGAPULS 69 can be equipped with an encapsulated plastic antenna or a lens antenna integrated in the metal flange. This enables the optimum adaption to different application areas.

Your benefit

- High plant availability, because wear and maintenance-free

- Maintenance-free operation through non-contact measuring principle

- Reliable measurement independent of vapour, dust and noise

Measuring range

Empty section. Edit page to add content here.Process temperature

Empty section. Edit page to add content here.Process pressure

Empty section. Edit page to add content here.Accuracy

Empty section. Edit page to add content here.Version

Empty section. Edit page to add content here.Materials

Empty section. Edit page to add content here.Downloads

Empty section. Edit page to add content here. -

A brain for the beverage industry

Continue Reading

Continue ReadingA brain for the beverage industry

Naturally, we’re also represented at the BrauBeviale 2015 in Nuremberg. Our F&B Industry Manager, Emilian Axinia, and his team will introduce comprehensive solutions with zenon for the Smart Brewery. They will demonstrate how our ergonomic software can function like the brain of the beverage industry 4.0 due to its flexibility and numerous interfaces.

Industry 4.0 also offers great opportunities and challenges for the creation of drinks: Ensuring competitiveness, resources and energy efficiency, quick adaptation to sales markets and increasing individualization. At this year’s BrauBeviale we will illustrate how the zenon Product Family is already supporting the Smart Brewery today.

But what characterizes a smart brewery of the future?

It can link local, intelligent systems to digital networks of machines and product components. It independently records data from its environment and then handles this within the production process. Production will thus become more flexible, small lot sizes can also be produced profitably, and predictive maintenance is organized by the machine itself. The ordering of materials as well as consumables, and even energy management, are becoming progressively automated. Machines that are designed to be open for different applications contribute to this. And software that can intelligently connect these machines and offer the human an ergonomic working environment.

Learn how to use the evolution of Industry 4.0

Part of a comprehensive software solution is not only to network all production areas but to provide comprehensive line management, batch control for creative brewing processes, monitor the OEE, as well as optimize energy consumption. COPA-DATA booth visitors can also test the HMI Multi-Touch technology for industrial environments first hand, and they can gain an overview of smart system architectures, where zenon data is connected from sensor right up to the cloud.

We look forward to seeing you at our booth and being able to let you become even smarter too!Source: Copadata.com

-

PLICSLED – The new switching status display module for point level sensors

Continue Reading

Continue ReadingWith the new display module PLICSLED, the switching status of a sensor can be read from afar, even in strong sunlight. The module is compatible with all sensors of the plics® family with relay output: VEGASWING series 60, VEGAVIB series 60, VEGAWAVE series 60, VEGACAP series 60 and VEGAMIP series 60.

Since external wiring is unnecessary, the time needed for installation is reduced to a minimum. Power is supplied via the relay electronics. The second relay output is used to control the switching status display. Depending on the module version, the switching status is displayed in the colour combination red-green or yellow-green.

PLICSLED is installed directly inside the plics® sensor housing, which gives it a high degree of protection from dust and water ingress.

-

VEGA Inventory System: New software for inventory visualization

Continue ReadingWith VEGA Inventory System sensors on tanks and silos can now communicate directly with the supplier – via a Web portal – and report the need for replenishment fully automatically and in good time.

Continue ReadingWith VEGA Inventory System sensors on tanks and silos can now communicate directly with the supplier – via a Web portal – and report the need for replenishment fully automatically and in good time.Vendormanaged inventory programs (VMI) are an efficient way of improving inventory monitoring and replenishment. The automated flow of information within a company or between partner companies creates transparency early on for the supplier – and security of supply for the purchaser. VEGA thus makes a strong link – with win-win effect – out of something that until now was a critical weakness in the supply chain.

With the help of the web-based software, the supplier assumes responsibility for the customer’s stocks and makes sure they are always sufficiently full. This arrangement gives him greater flexibility in his own resource and logistics management. He no longer has to depend on the customer assessing his needs accurately and ordering replenishments on time. VEGA Inventory System takes over this function. To accomplish this task, the software provides automatic alerts to the supplier.

The program also includes a series of well-designed analytical and planning tools that enables optimized demand, inventory and delivery planning.

Source: VEGA.COM